To start off, I unpacked the cylinder (an SHS brand steel one in case anyone is interested). I had read that polishing the inner surface is a good idea, and luckily I had some 0.3 micron lapping film left over from when I tried to sharpen my straight razor years ago. It worked pretty nicely and after a while I had a pretty nice shine going.

I then opened up the gearbox. This time I managed to keep the spring in check with a screwdriver and also remembered to release the tappet plate spring, so no parts flew out today. Again using the Scho-Ka-Kola tin, I collect all the small pieces so as not to lose anything.

A quite a while earlier I had already bought an aluminium piston and piston head which I thought would be great replacements for the originals. But as it turned out, I couldn't use them without a new spring, because the original spring has a twist on the end and as such was only compatible with the original piston assembly.

Now that I had the new spring, so I could finally get to work. But it wasn't that easy, of course. As it turned out, the piston I had was not exactly round, but rather flattened on the end. It also had some strange pitting in places, so I slowly began to question its quality. Since the piston was not round, it wouldn't slide freely in the gearbox, instead getting stuck around halfway. At least I was smart enough to test it out before putting the whole box back together only to then wonder why it is not working.

|

| Metal piston, 1, non-round |

I started fixing the piston by simply sanding the sides, hoping this would give me enough clearance, as well as make the piston slide better due to added smoothness. It didn't really do the trick, though. It was still getting stuck on the sides when the gearbox was kept closed by simple finger pressure alone. Something else had to happen, clearly. I reasoned that I could reshape the piston with some pipe pliers once they're set to proper size. It turned out to actually work, as I slowly progressed from the end towards the head, carefully pressing down from several angles.

|

| Sanded and reshaped with pliers |

The piston was now at least round enough to move freely. Attaching the piston head was a rather simple feat involving a screwdriver and some finesse. The piston head sat a bit crooked on the piston, though, so I had to take it back off again. The crookedness was alleviated by adding a thin metal washer behind it.

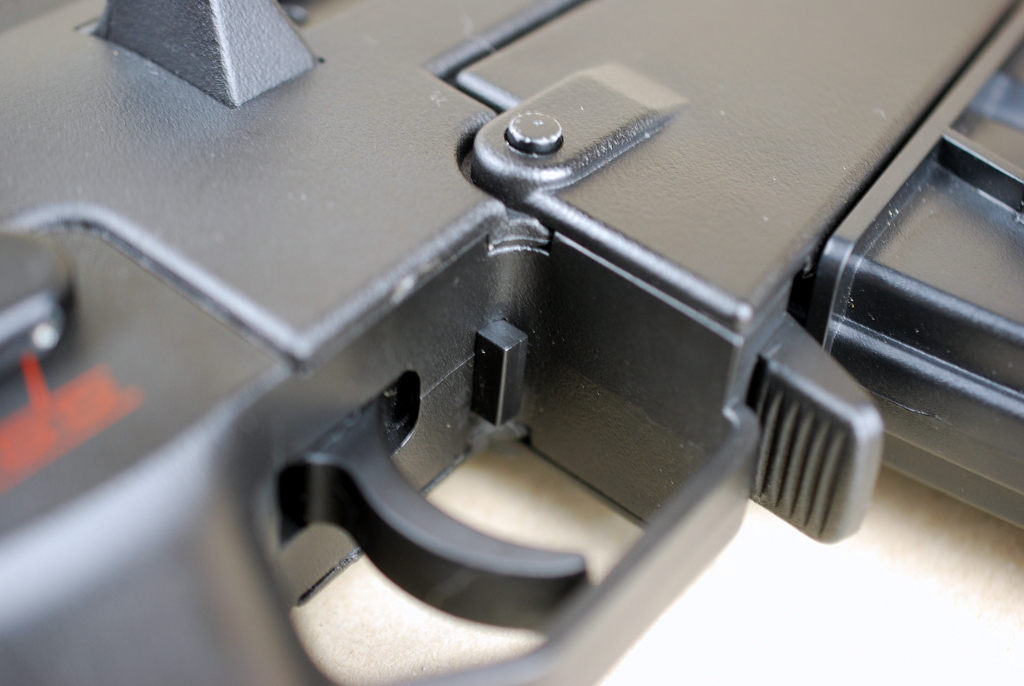

Next, finally, came the spring. I was most eager to finally get a proper spring in so I could really start making the AUG into a DMR (and being able to bring it back into games as well). I soon found the error in my thinking, though.

The default spring guide in the AUG is a plastic one. It's sturdy enough to hold the default spring in check, but the new, stiffer one was much too much for it to handle. As soon as I managed to stuff the new spring in and ever so slightly let go of it, the natural tendency of the spring to extend did the spring guide in. The only thing holding the spring in place was a small plastic tab on the rear of the spring guide, which was mated with a hole on the gearbox shell. As you might have guessed, it was no match for the spring at all. So out popped the spring and off popped the tab. Determined to get this thing together today, I picked up the gears that had flown out, placed them back in, and retried the whole operation. I turned the spring guide around to use the other tab that was still in place, but very soon got the exact same result. So now I was left with a spring guide with no tabs on, and a spring that I could not keep in place long enough to actually put the gearbox back together.

|

| The sorry excuse for a spring guide. You can clearly see where the tab used to be on this side |

I just had to admit defeat and put the old spring and piston back in, again. At least the new cylinder was in so there was at least some improvement over from where I started. The trigger pieces made me want to pull my hair out, again, because it took several tries to actually get them to sit still long enough to line up the gearbox shell and all the pieces inside. If the gears were properly aligned, the trigger pieces weren't and vice versa.

I finally got it back to working order, though, and sighed in relief. This thing is starting to drive me nuts, seriously. A steel spring guide is on order, so I'll get back on this once it arrives.