Patient: Tokyo Marui AK-47

Symptoms: Without trigger pull, begins firing as soon as selector is moved off from safe

The non-metallic body issues were quite nicely alleviated, however, by the fact that out of the four metal "hi-cap magazines" that accompanied the gun, only one was actually a rattling BB bottle, and the other three were proper Marui regular size mags (holding around 70 BBs). I had prepared to resell the useless mags and get proper ones at a later point, but now there was no need.

All the original wood imitation externals and the bolt carrier had been painted black (poorly) and the paint on most of the magazines had worn down quite nicely. This immediately sent my mind on a trip to a post apocalyptic setting or a STALKER themed game. That is actually the look I'll be going for with this thing, more on that in another post later.

Day 1

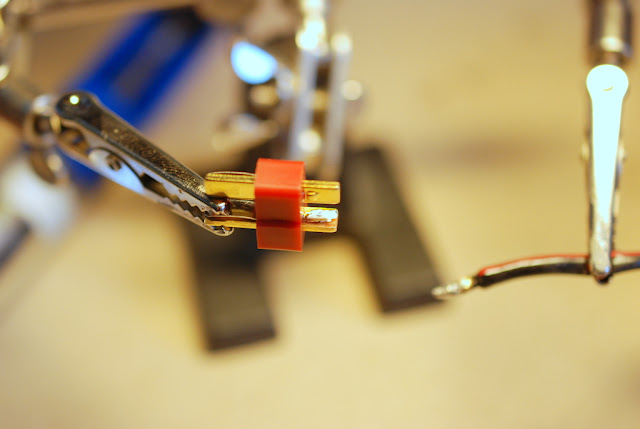

The gun came with the large Tamiya connector, but with no batteries, as I purposely did not want to have the previous owner's NiMHs lying around, since I've moved on to using LiPos rather exclusively. All the batteries that I had, though, naturally had the mini Tamiya connectors, so I could not test fire the gun at all.Since I had been toying with the idea of changing all my guns and batteries to Deans connectors anyway, this seemed like the perfect time to take my first steps in that direction.

The old connector came loose pretty nicely by just pulling on it with pliers, which saved me the trouble of having to strip the wires. After that, it was just a case of soldering the new connector on.

The helping hands are a life saver when you need to solder stuff onto other stuff, and I quickly had the connector on. Next was the battery. I decided to use an old, low power NiMH battery as a test bed, so as to not mess up a more expensive and much more useful LiPo. All went well, though (which, considering this blog, is rather unusual). Pretty much the only two things I could have screwed up, though, apart from forgetting the shrink wrap, were to either solder the connector pins on the wrong way, or worse, cut both battery wires at the same time, shorting the battery with the cutters in the process. I hear the latter especially is possibly a Bad Thing™.

Since I luckily managed to avoid both of the above, I now finally had some juice to fire up the AK for the first time. I turned the selector down from safe, and sure enough the thing started shooting right away. Something was obviously pretty wrong on the inside.

I unplugged the battery and began educating myself on how to open up the gun so I could get to the internals and figure out what was going on. Turns out it's not too hard to do, but I managed to break something in the process. I didn't unscrew the hop up adjustment tab, which when I tried to get the cover off, bent finally and broke the plastic piece of the cover that has the graduated sticker on it. No real problem, though, it's not really a functional part.

As I continued taking the gun apart, it became apparent that the/a previous owner had painted the gun with all the parts still on, as is evident from the image above showing the part of the body that was under the fire selector. The gas tube inside the front handguard also had some interesting splatter pattern going on.

Once I got the gearbox out of the gun, it began looking as though the gun had never been taken apart even once.

The dirt and grime in the picture above continued on the inside as well. What isn't shown here is the fact that the GB shell was held together with Torx head screws, not the usual Phillips ones. Guess that might have deterred a less enthusiastic mechanic, but not this one.

As I separated the gearbox shell halves, it was pretty clear something was in the wrong place. How the spring (between the spur gear and the end of the piston above) had managed to stay out of the gears so far was definitely beyond me, but I was certainly happy that it had.

A pretty clear picture of what was (most) wrong with the gun had now formed. The trigger switch return spring had broken just from the end where it's hooked on the post of the GB shell. Before figuring out what to do with it, though, I went through the other parts in case they needed cleaning or replacing.

The head of the piston was covered in a grimy, oily residue which had bits of dirt stuck on it all around. It was almost as if I was looking at an AK that had been subjected to a real steel torture test.

The extremely dirty piston had naturally also ground away at the cylinder wall, which was full of scratches and this one weird, large, deep scratch.

The light alloy sector gear (pictured from the flip side above) had its last tooth worn down cleanly, apart from a small flange that had been left behind. One more for the pages of the upcoming international bestseller Never Seen That One Before. The gun had basically short stroked itself somewhere along the way.

The dirty insides continued with the nozzle, the contents of which are seen above on the two ends of the Q-tip. I didn't dare even look inside the barrel at this point.

The trigger contacts had also certainly seen better days. The pitting is pretty extensive in my opinion. I took a small file to the metal it and filed it back down to a smooth surface on both sides.

I soaked all the metal parts in brake cleaner to get the old grease and dirt off. All of that residue is seen above. I was sure the gun would work a bit better without all that inside. Or was this in fact the mystical Marui magic dust without which the gun was ruined? Only time would tell.

As mentioned above, the trigger switch return spring had broken completely. It did look like it had also been between the gears at some point, as is evident from the bending above. Since I didn't have a replacement spring, my first thought was to see if I could re-use use this spring somehow.

I took two pairs of small pliers and bent the broken spring somewhat, so that the shape again resembled that of the original.

After a bit of fitting and cursing, my fancy makeshift repairs seemed to certainly do the trick! The switch was sliding back and forth just the way it should.

Since I hadn't located any other problems on the gun, I came to the conclusion that the always-on trigger was the only culprit, and began putting the gun back together, because I wanted to test fire it now with all the parts functioning.

Everything went pretty smoothly there, I re-greased everything and quickly tested the compression, which turned out to be surprisingly good, apart from the nozzle which had no o-ring.

Once I had the gun in one piece again, I set up the chronograph to see what kinds of results I would get.

With an 0.20g BB, the chrono read around 80 m/s (262 FPS), and with a 0.25g, 70 m/s (230 FPS), so around 0.6 J. It was obviously rather underpowered even by Marui standards, but this was to be expected with the self-short-stroking sector gear, the leaky nozzle, and what must be the original hop-up bucking. Since I had no replacement parts, I set the gun aside until I found some, particularly a new sector gear and spring.

Day 2

As luck would have it, I got some very slightly used second hand standard XYT steel gears and a new plastic piston and piston head for pretty cheap, and a completely unused second hand Vanaras green spring, which corresponds to an M110. I also happened upon a bundle of three more Marui metal regular capacity magazines, which brought my total to six. Those should certainly last a while for sure.

This time when I took the gun apart to install the parts, I also took care to unscrew the hop-up adjustment nub. It made removing the cover a whole lot easier.

Since the gun had originally also come with plastic bushings, I ventured to change those. As luck would have it, I had a set of 6mm ball bearings lying around from when I began working on the AUG and had mistakenly ordered the wrong size. It's good I have a hard time getting rid of stuff.

With the new(ish) parts in hand, I set to work. I decided to re-shim the gearbox as well while I was at it.

After everything was set and the GB was back together, I noticed the motor had some trouble turning the stronger spring. At first I thought this might have something to do with the plainly sucky NiMH battery I was using so, encouraged by my success with earlier soldering, I decided to put a Deans connector on a stick LiPo as well.

Even with a fully charged LiPo the motor would occasionally not cycle all the way on semi-auto. Again my scavenging nature came in handy, however, as I still had the original motor from the AUG.

Changing the motor (naturally) brought on a new, interesting problem. Since I had shimmed the gun using the Marui motor, and the AUG motor was just slightly different spec, the pinion gear now connected much too tightly with the bevel. Furthermore, the AUG motor sat ever so slightly higher than the Marui original that even turning the motor height adjustment screw all the way down was not enough.

Rather than reopen and re-shim the whole gearbox for a second time, I opted for another solution. I took the motor out of the cage, and screwed off the adjustment set screw.

The screw head was a raised one, so I took out my trusty file set again and went to work.

After some ecstatic rubbing, I had managed to make the tip disappear. With the new flat headed adjustment screw, the motor was able to sit low enough to mesh with the gears very nicely, and I finally got the GB to cycle with the LiPo. And it did it ever so nicely. After a bit of height adjustment, the sound of the GB cycling also became very smooth, which I was definitely happy about.

The gun had originally been wired to the rear, but I didn't like the hollow sound of the stock or the fact the battery was bouncing around in it, and thus made one final move, to rewire the gun to the front. This would also allow me to use the same stick LiPo I had bought for the MP5.

After some cutting and soldering, and some more soldering, and finding a new place for the fuse, I finally had everything back in working order. Then I naturally had to chrono the gun again to see the fruits of my labour.

I was slightly disappointed to see that I was "only" getting around 92m/s (302 FPS) on a 0.25g, which is about 1.06 J, but at least the figures were on an incredibly small spread. I had a few times when two consecutive shots both read the same exact speed down to the tenth of a second.

Despite the test results, I declared this leg of the project done at this point. After all, the gun was now fixed and was performing a whole lot better than it had when it arrived. It was ready to be taken out to the field at the first sight of opportunity. Later on, I will definitely still check and most likely change the hop-up bucking and the nozzle, which should both increase compression and will most likely get the gun to the expected power range of around 1.2 J, or around 100m/s on a 0.25g.

In a later post I will also get back to the visual modifications I have in store to properly post-apocalyze this gun and the magazines for end-of-the-world scenarios.